How to Fix Bad, Stale, and Uncertain Tags

Why Tag Quality Matters

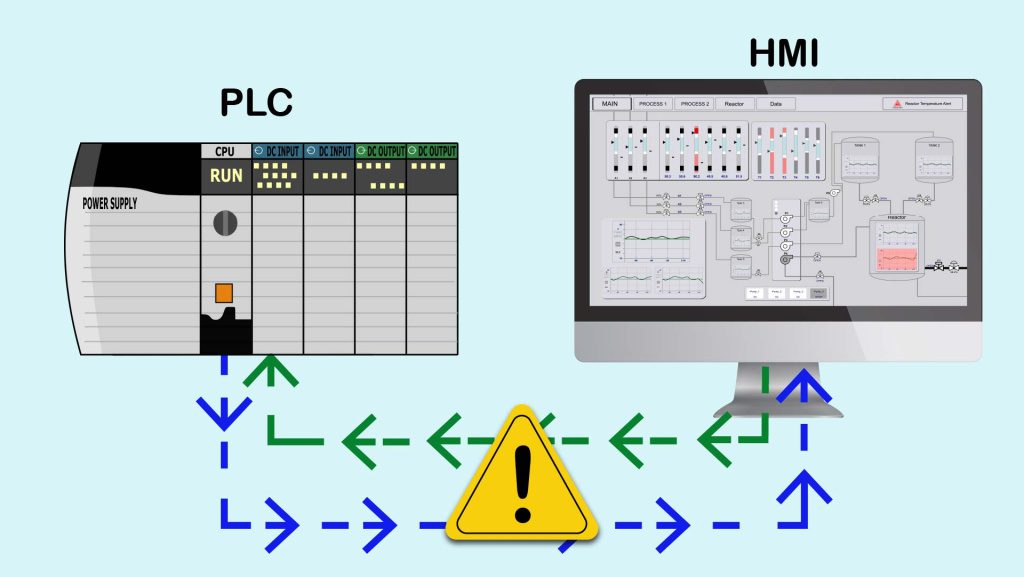

If your tags in Ignition show up as Bad, Stale, or Uncertain, you’re not alone. These quality states are more than just red icons; they’re critical diagnostics. Effective Ignition tag quality troubleshooting can prevent false alarms, stale data, and communication breakdowns before they spiral into downtime.

These tend to surface at the worst possible moments, such as during a shift change, just before an alarm, or when trying to log a critical event. That’s why understanding and diagnosing tag quality issues quickly is essential.

This guide takes you through the five most common causes of Ignition tag quality issues and provides a proven workflow to quickly resolve them, whether you’re working with OPC tags, PLC communication, or derived values.

Top 5 Causes of Tag Quality Issues in Ignition

- OPC Server or Device is Unavailable

If the OPC server connection is lost or the device itself is offline, all associated tags will return a bad quality. Check for:

- OPC server faulted status in the Gateway

- Device status in the OPC Connections page

- Network interruptions or power loss at the PLC or RTU

🔗 Using OPC Connections in Ignition

- Tag Path is Incorrect or No Longer Valid

This issue can affect almost any Ignition tag type: OPC, expression, derived, or UDT instances. If the path to the data source changes but the tag definition isn’t updated, the tag will fail.

Common causes include:

- A change in the tag name or address in the PLC

- A renamed folder or structure in Ignition

- An outdated or broken connection path to a UDT, device, or tag provider

In many cases, the tag still exists, but Ignition is pointing to the wrong location. This misalignment typically triggers a Bad_NotFound quality.

🔍 Tag Properties: OPC Item Path, Bindings, and References

- Data Type Mismatch or Write Permission Error

If the tag is trying to read or write a value using the wrong datatype, you may see “Error_TypeConversion” or similar. Also, writing to a read-only address (especially in Modbus or PLC registers) can trigger tag errors.

- Device Communication Issues

Dropped packets, long timeouts, or serial port misconfiguration can cause tags to update sporadically or return stale values. For example, a poorly performing Modbus TCP device may intermittently time out.

📈 OPC UA Device Diagnostics Tags

- Misconfigured Scan Class or Execution

Settings

Tags tied to the wrong scan class, or one executing too frequently or not frequently enough, can lead to unexpected behavior. A tag might appear stale if its execution rate is too slow for the system’s needs.

A Simple Troubleshooting Workflow

Once you spot a tag showing Bad, Stale, or Uncertain quality in Ignition, follow this step-by-step process to narrow down the root cause:

- Check the Tag Quality Code

Hover over the tag’s quality indicator in the Ignition Designer or Tag Browser. . This code is your first clue; log it before making changes.

- Validate the Data Source

- For OPC tags, check the OPC connection status in the Gateway (Config > OPC Connections)

- For other devices, go to Config > Devices

- For expression or derived tags, open the binding or expression editor and verify the logic or references

- For memory tags, ensure they aren’t accidentally bound or overridden

- Test Device Communication

- Ping the device from your network (or test with a known-good OPC client if possible)

- Review the device’s diagnostic logs if the connection is unstable

- Review Tag Path and Data Type

- Make sure the tag path is valid and hasn’t changed (especially UDTs or renamed folders)

- Ensure the data type matches what the source is sending – e.g., don’t expect a Boolean if the PLC is sending an Int

- Check Execution and Scan Class

- In the Tag Editor, verify the tag’s execution rate or scan class.

- Too slow, and tags appear stale or unresponsive. Too fast, and the device may drop connections or overload the Gateway.

Not sure what scan rate to use? These general guidelines can help you match polling frequency to tag behavior:

| Tag Type | Suggested Rate |

| Status Indicators (digital inputs, alarms) | 500ms – 1s |

| Analog Values (temperatures, pressure, etc.) | 1s – 5s |

| Setpoints or infrequently changing values | 5s – 10s |

| Calculated or derived tags | As needed, often 5 – 10 s |

- Also, check if the tag is disabled or if the scan class is stuck in an error state (visible in the Gateway under Tags > Diagnostics)

Bonus Tip: Use Ignition’s Built-In Diagnostic Tools

- Tag Diagnostics – Check quality codes, execution time, and status

- OPC Diagnostics – See real-time updates and error messages

- Gateway Logs – Look for timeouts, path errors, or server disconnects

- Threads & Metrics – Detect overload scan classes or execution lag

This process covers 90% of the tag quality issues we see in the field. The following section will show a real-world example of how this workflow can trace and resolve a persistent Modbus tag issue.

For more information, dive into the Ignition User Manual.

Preventative Tips to Avoid Tag Quality Issues

Once you’ve resolved a tag quality issue, the next step is ensuring it doesn’t happen again. Here are a few habits and configuration practices that can help:

Use a clear folder structure and consistent naming conventions. This makes it easier to spot misconfigured tags, track dependencies, and apply scan classes or alerting at the folder level.

If a device or protocol (like Modbus) struggles with fast polling, slow it down:

● Start with 1s or slower and adjust based on need

● Group slow-changing tags into a separate scan class to reduce load

Use tag event scripts or system alarms to notify you when tag quality drops below Good. Even a simple alert for != Good can help catch problems before they cause downtime.

Ignition includes tools to help catch issues early:

● Tag Diagnostics: View last execution time and quality

● OPC Diagnostics: Track response times and failures

● Gateway Logs: Search for device timeouts or permission errors

Changes to UDTs or nested structures can silently break tag paths. Always test dependent tags after making edits to templates or structures.

You don’t need to overhaul your entire tag database to see benefits. Even a few of these changes can prevent the next mystery Bad_Stale from ruining your shift.

Need More Troubleshooting Tips Like This?

Tag issues don’t always show up when it’s convenient—but knowing what to look for can save hours of frustration.

👉 Subscribe to get our monthly SCADA tech tips delivered straight to your inbox.

We cover Ignition, PCS7, Modbus, OPC, and more—with practical advice for real-world systems.

Still dealing with Bad or Stale tags in Ignition? Talk to our SCADA experts about how to stabilize your system and resolve persistent tag quality issues.