PCS7 Systems are powerful, but only if they’re set up right.

Most failures we encounter are not due to hardware or code but rather to small, avoidable mistakes: mismatched IPs, inconsistent naming, missed time synchronization, or download errors.

The six best practices below will help you build a stable foundation and keep operations running smoothly.

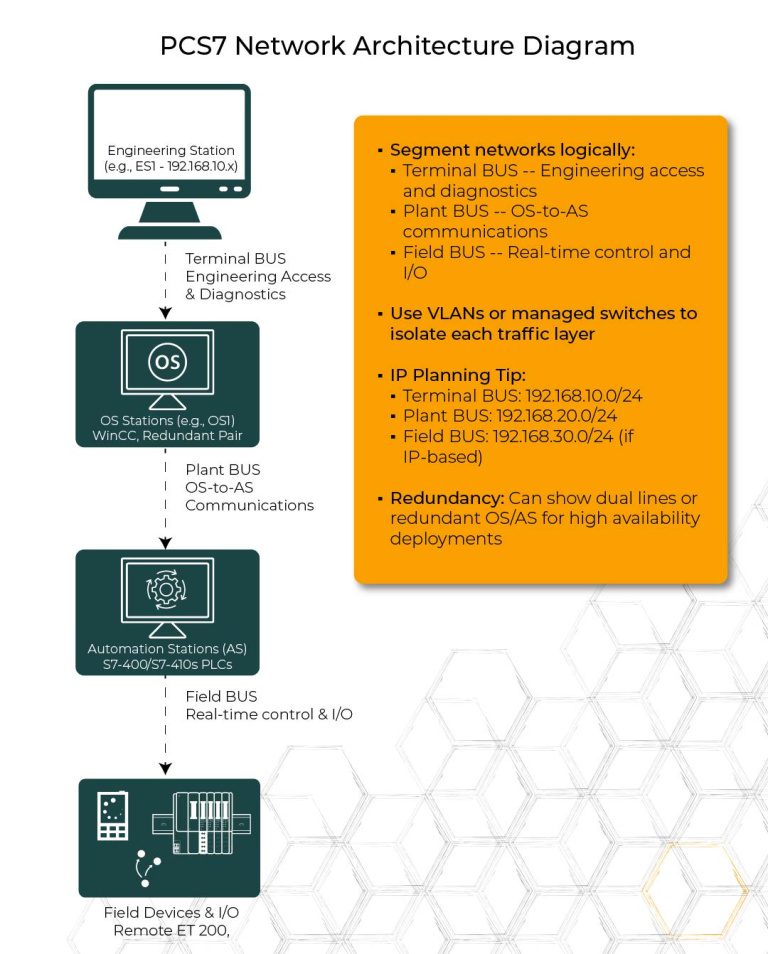

1. Define a Clean Network Architecture Early

A well-structured network is the backbone of a stable PCS7 system. If this step is skipped, communication issues become nearly inevitable.

What to focus on:

- Segment your networks: Separate OS, AS, and field-level traffic using managed switches or VLANs. This reduces collisions and simplifies troubleshooting.

- Standardize IP schemes: Use consistent, documented IP ranges for each network layer (eg., TerminalBUS, PlantBUS, and PROFIBUS).

- Align subnet masks and gateways: These must match across each segment; one mismatch can silently break communications.

Why it matters:

Good network planning upfront prevents hours of network troubleshooting later and makes future scaling far easier.

📘 Further reading:

Configuring S7 Communication via Industrial Ethernet (Siemens Support)

2. Build Redundancy into Critical Components

Even with a perfectly configured PCS7 system, failures can, and do, occur. That’s why designing for redundancy is one of the most important steps in protecting high-value operations.

What to focus on:

- Redundant OS Stations: Use WinCC OS Redundancy to ensure continuous HMI and data logging if one node fails.

- Redundant communication paths: Design dual Ethernet rings or use redundant SCALANCE switches to maintain network access even if a link is lost.

- Redundant CPUs and power supplies: In critical applications, use fault-tolerant SIMATIC S7-400H or S7-410 systems paired with redundant power to eliminate single points of failure.

- Document failover logic: Redundancy should be seamless to operators, but engineered, tested, and documented by the team.

Why it matters:

Redundancy minimizes disruption during maintenance, updates, or hardware faults. It’s not just a backup plan, it’s a stability strategy.

📘 Further reading:

Redundancy in WinCC V7.x and WinCC Professional (Siemens Support)

Note on Operating Redundant SIMATIC S7-400H with ET 200SP HA Modules

3. Use Consistent Naming and Station Configuration

Names in PCS7 aren’t just labels; they’re critical to how components connect. One typo can stop an OS from talking to an AS.

What to focus on:

- Match project and computer names: The Windows PC name must match the station name in the PCS7 project.

- Avoid mid-project renames: If you must rename a PC or AS, update it everywhere –HW Config, NetPro, and OS assignments—and redownload.

- Use a naming convention: Define standard names for OS stations, AS nodes, subnets, and tags to prevent future confusion.

Why it matters:

Even a one-character mismatch can block communications. Consistent naming ensures everything talks to the right place.

📘 Further reading:

PCS 7 Engineering System – Basics Manual

4. Centralize Time Synchronization Across All Stations

Inconsistent clocks can cause events to appear out of order, or disappear entirely.

What to focus on:

- Designate a central time source: Use an SNTP server (Simple Network Time Protocol) or a designated AS to sync all nodes.

- Use consistent time settings: Choose one method (NTP or SIMATIC Time Sync) and apply it across OS and AS stations.

- Sync engineering stations too: Keep PC clocks aligned with the rest of the system to avoid versioning and log confusion.

Why it matters:

Accurate time means accurate data. Syncing ensures reliable diagnostics, event logs, and alarm tracking.

📘 Further reading:

PCS 7 Engineering System – Basics Manual

5. Validate Communication Paths with Siemens Tools Before You Download

Even perfect configurations can fail if the interfaces or routes aren’t right. Always test before you deploy.

What to focus on:

- Use PG/PC diagnostics: Confirm your engineering station can reach each device before downloading.

- Check NetPro connections: Assign interfaces correctly and run “Check Consistency” before compiling.

- Test PROFINET/PROFIBUS: Use PRONETA or PN-Diag to identify unreachable devices, address conflicts, or wiring issues.

Why it matters:

Never assume communications will work out of the box. A few minutes of validation saves hours of debugging.

📘 Further reading:

PRONETA Tool – Siemens Download

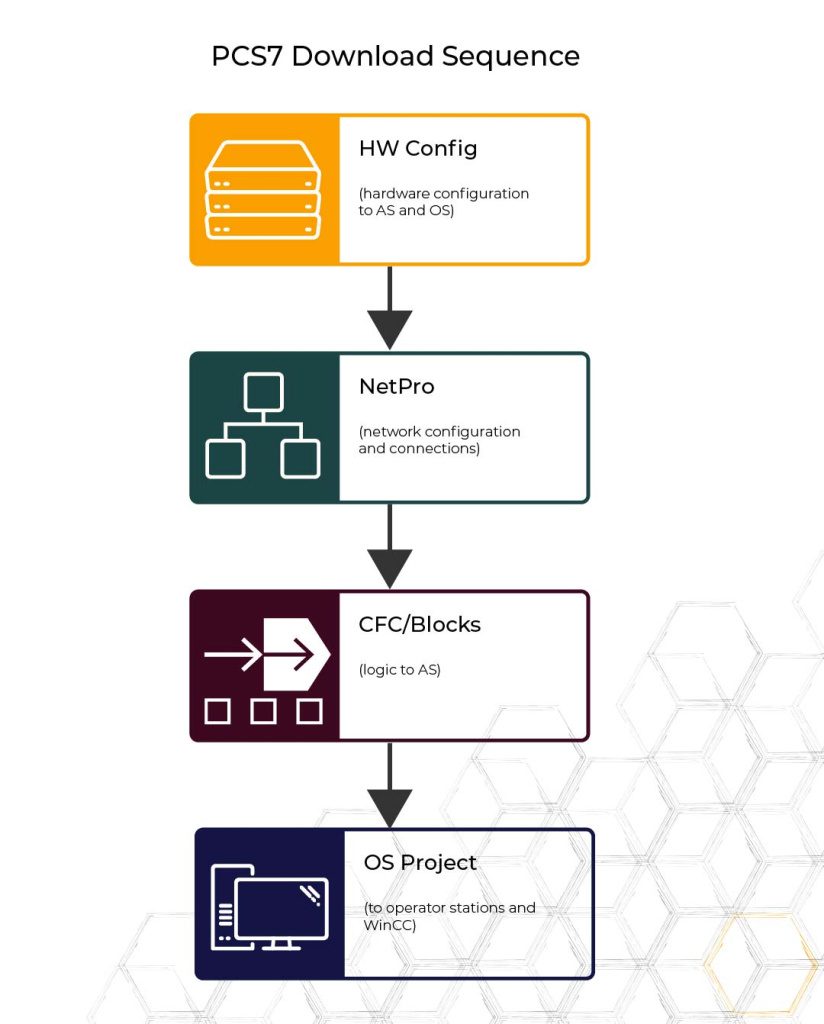

6. Download in the Right Order and Document Every Step

Even well-set configurations can misbehave if the wrong download sequence is used, or if no one remembers what changed.

What to focus on:

- Follow Siemens’ download order:

- HW Config (hardware configuration to AS and OS)

- NetPro (network configuration and connections)

- CFC/Blocks (logic to AS)

- OS Project (to operator stations and WinCC)

- Redownload after changes: Any structural updates require a full recompile and redeployment

- Keep a commissioning log: Record who changed what, when, and why. This is a lifesaver during testing and audits.

- Follow Siemens’ download order:

Why it matters:

Skipping steps or forgetting what changed leads to hidden bugs. A structured process keeps things reliable.

📘 Further reading:

Wrap-Up: Set It Up Right, Avoid the Fire Drills Later

PCS 7 is a powerful platform, but it doesn’t forgive setup shortcuts. The most common failures we see in the field aren’t due to broken hardware or bad code. They come down to basic setup practices being missed or rushed.

Ensure your project’s success by following these five best practices:

✅ Plan your network

✅ Design with redundancy

✅ Use consistent naming

✅ Synchronize your time

✅ Validate communication

✅ Download correctly and document—it pays off in reliability, uptime, and easier troubleshooting down the road.

Get More Like This

We publish hands-on tips for PCS7, SCADA, and industrial automation systems—designed to help control engineers troubleshoot faster and build smarter.

Want practical insights like this delivered straight to your inbox?

Subscribe to our monthly Tech Tips for real-world strategies, system guides, and zero fluff.

The Best Five Minutes You Can Spend: PLC Health Check

TL;DR A five-minute PLC health check can catch early warning signs before they cause downtime. Reviewing diagnostics, tag quality, alarms, time sync, and backups helps

The Complete Roadmap to Smarter SCADA in 2026

Ignition is evolving fast — and 2026 is the time to plan ahead. This roadmap walks you through assessing your system, setting aligned goals, and upgrading with confidence, so your SCADA stays secure, reliable, and ready for what’s next.

No More Guesswork: Proven Plays to Train and Empower Operators

As veteran operators retire, the skills gap is widening. This playbook shows managers how to train and empower new operators with mentorship, practice, documentation, and culture — building confidence that keeps plants reliable and resilient.