Ignition is advancing faster than ever — with new Solution Suites, major announcements at ICC 2025, and features that continue to raise the standard for industrial SCADA. For plants, that rapid pace is both opportunity and challenge. The platform offers more flexibility and power, but it also requires careful planning to stay aligned with version updates, security requirements, and infrastructure changes.

That’s where planning makes the difference. As a Gold Certified Integrator, Pigler Automation helps plants turn Ignition’s evolution into a steady, dependable path forward. This roadmap outlines the steps every plant manager should consider now to secure funding, avoid disruption, and get the most from Ignition in 2026.

Table of Contents

Step 1: Assess Where You Are Today

Every roadmap starts with a baseline. Before mapping where Ignition should take you in 2026, it’s important to know exactly where your system stands.

Version Check

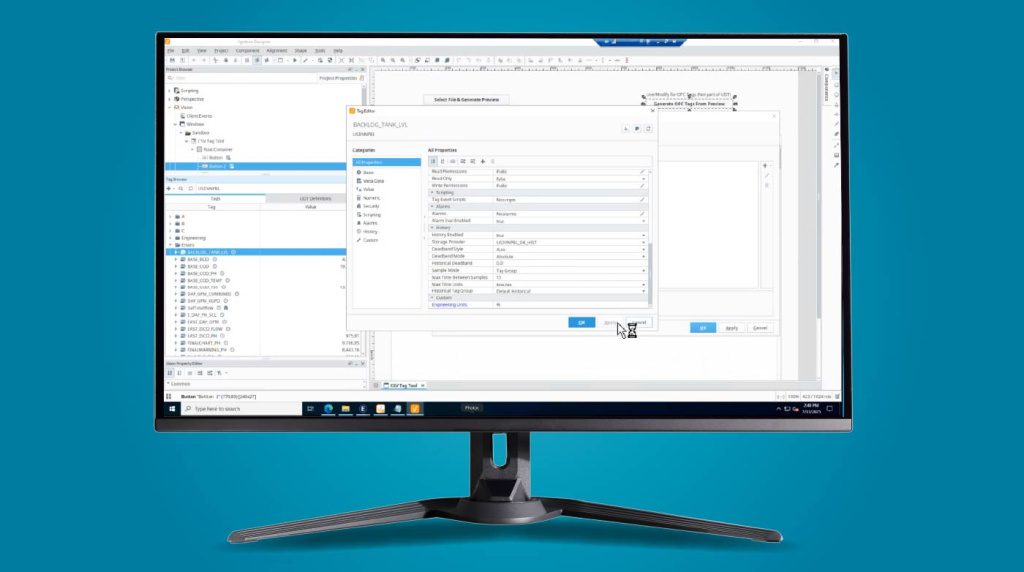

- In the Ignition Gateway, open Status → System Info to see your current version.

- Compare it against Inductive Automation’s release notes.

- Running more than two versions behind often means limited patch support and security risks.

Infrastructure Review

- Check server operating systems and virtualization platforms — are they still supported?

- Review CPU and memory load in the Gateway; consistent high usage signals the need for scaling or refresh.

- Don’t stop at SCADA: review PLCs and control systems (Siemens, Rockwell, Beckhoff, etc.). Outdated firmware, unsupported CPUs, or fragile networks can undermine Ignition stability just as quickly as old servers.

- Document dependencies like databases and third-party modules; unsupported versions can bottleneck otherwise healthy systems.

System Health

- In the Tag Browser, look for tags with “bad quality” or “stale” status.

- Check alarm pipelines for recurring nuisance alarms — often a sign of configuration drift.

- Review gateway logs for recurring errors that may not yet disrupt operations but could complicate upgrades.

💡 Often Overlooked:

Even if Ignition is current, the underlying infrastructure and control layer may not be. Unsupported OS builds, outdated firmware, or legacy database drivers can destabilize an upgrade. Confirm the foundation — from servers to PLCs — is as ready as SCADA itself.

Step 2: Define Your 2026 Goals

Once you know where your Ignition system stands, the next step is to define where you want it to go. An upgrade isn’t just about running the latest version — it’s about aligning SCADA improvements with broader operational goals.

Start with the “Why”

- Strengthen security and patch vulnerabilities.

- Improve reliability and reduce downtime.

- Scale to new sites or higher production.

- Expand analytics or MES integration.

- Coordinate with control-layer projects (e.g., Siemens CPU refresh, Rockwell migration, Beckhoff expansion).

Turn Goals into Measurable Outcomes

- Security: fewer vulnerabilities, stronger audit compliance.

- Reliability: higher uptime, fewer nuisance alarms.

- Efficiency: faster operator workflows, streamlined reporting.

- Scalability: clear path for licenses, modules, or sites.

- Integration: smoother coordination between SCADA and control systems.

Why Goals Drive the Roadmap

Upgrades that start with clear goals deliver more than technical improvements. They justify investment, align teams, and ensure supervisory and control systems evolve together.

📊 Pro Tip:

Tie each goal to an outcome leadership cares about. Example: “Reduce unplanned downtime by 5% in 2026 through SCADA and PLC lifecycle alignment.” Framing goals in business terms — and linking across layers — makes upgrades easier to fund and defend.

Step 3: Map the Upgrade Path

With goals in place, the next step is choosing the upgrade path that gets you there. Ignition’s flexibility means there isn’t just one way forward — the right path depends on your system’s current state and 2026 objectives.

Options to Consider

- Minor Updates: Stay current with patches for stability and security.

- Major Upgrades: Adopt new features and ensure long-term support.

- Module Expansion: Add capabilities like Perspective, reporting, or MES without a full SCADA overhaul.

- Hybrid Approach: Combine smaller updates now with a larger upgrade during planned downtime.

Don’t Forget the Control Layer

Ignition sits on top of Siemens, Rockwell, or Beckhoff systems. If those platforms are nearing end-of-life or migrating to new hardware, that directly impacts the Ignition timeline. Align supervisory and control roadmaps to avoid mismatches that surface only after an upgrade.

How This Shapes Your Roadmap

Defining the path gives structure. Instead of treating modernization as a one-time event, you can sequence upgrades in manageable steps that reduce risk and deliver value sooner.

🛠️ Field Insight:

Plants that save everything for one “big cutover” often face more downtime and operator confusion than expected. A staged approach spreads the work, reduces disruption, and helps teams adapt gradually.

Step 4: Align Within Existing Plans

Most plants map out major shutdowns years in advance — with every maintenance window tightly orchestrated. The challenge isn’t deciding if Ignition should be upgraded, but how to fit it into plans already on the calendar.

Look for Natural Touchpoints

- Pair Ignition upgrades with control-system migrations, server refreshes, or cybersecurity projects.

- If infrastructure updates are already budgeted, align SCADA work with that same window.

- Where long shutdowns aren’t feasible, use partial upgrades — modules, redundancy, or test environments — to keep moving forward.

Work With the Timeline

- If your next full plant shutdown isn’t until 2027, use 2026 to build, test, and validate Ignition in parallel.

- Treat budget cycles as prep time: lock in funding, stage equipment, and be ready to execute when downtime arrives.

The Payoff of Alignment

Upgrades succeed when they move with the rhythm of the plant. By nesting Ignition work inside existing plans, you minimize disruption and keep modernization sustainable.

⏳ Timing Tip:

The best time to plan a SCADA upgrade isn’t during the shutdown — it’s the year before. Aligning Ignition with projects already on the books prevents last-minute budget scrambles and ensures everything is ready when the plant goes dark

Step 5: Put the Roadmap Into Action

A roadmap only works if you have the right guide to help navigate it. Ignition upgrades touch licensing, infrastructure, and operator workflows — and experience makes the difference in bringing all those pieces together. That’s where Pigler Automation comes in.

Over the years, we’ve developed practical ways to take uncertainty out of SCADA lifecycle planning. Our AUDITIQ™ assessment provides a structured baseline and clear upgrade priorities, while the SCADA Project Workbook gives teams a framework to capture requirements, tag strategies, and architecture decisions . Together, they turn planning into action.

🤝 Trusted Approach:

As a Gold Certified Integrator, Pigler has the perspective and proven methods to guide Ignition users through lifecycle planning. With the right map and the right partner, upgrades shift from disruption to confidence in your plant’s future.

Your Next Move

Planning ahead now means fewer surprises in 2026. With a clear roadmap, practical tools, and Pigler as your guide, Ignition upgrades become a natural step forward instead of a last-minute scramble.

Ready to Start Your 2026 SCADA Roadmap?

Turn your plan into action with out step-by-step Ignition planning tools and expert guidance