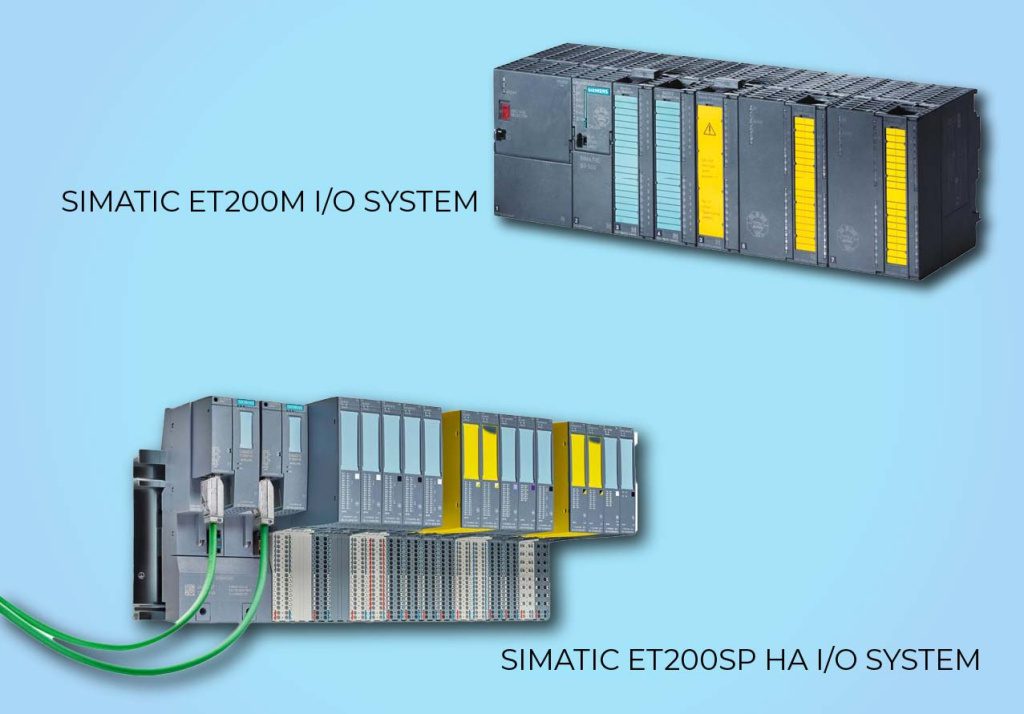

SIMATIC ET 200M Replacement & Modernization

The Deadline Is Real – But So Are the Challenges

If you’re still using a SIMATIC ET 200M system, you’re not falling behind – you’re facing a decision that affects wiring, cabinet layouts, downtime periods, and how your entire system operates.

That’s why we’ve created this resource: to guide you through your options, emphasize key tradeoffs, and provide the tools to plan your next steps confidently, not on guesswork.

Here you’ll find Siemens-backed upgrade strategies, technical considerations, and planning guidance designed to help you align your modernization approach with your plant’s actual readiness.

Whether you’re planning a full I/O replacement or aiming to extend your system’s lifespan through a phased approach, this serves as a starting point based on real-world constraints.

Three Strategic Ways to Move Forward from SIMATIC ET 200M

There’s no one-size-fits-all method for replacing ET 200M. Siemens recommends three upgrade strategies, each with tradeoffs in complexity, cost, downtime, and long-term flexibility.

🔹 Option 1: Full Replacement

Best for: Sites with available downtime and cabinet access, or already running newer CPUs and Profinet

What it involves:

- Replace ET 200M I/O with ET 200SP HA

- Migrate from Profibus to Profinet

- Rewire cabinets, update field connections

- Upgrade to PCS 7 v10.x (recommended by Siemens) for long-term support

What to consider:

- Cabinet redesign may be required

- Full symbol mapping and project updates

- Best long-term support and redundancy capabilities

🔹 Option 2: Software + CPU First

Best for: Plants not ready to replace I/O, but needing to extend supportability and prep for future changes

What it involves:

- Upgrade CPUs (e.g., to S7-410-5H)

- Upgrade PCS 7 to v10.x if possible (v9.x minimum)

- Enable Profinet, APL blocks, and redundancy features

- Prepare system for future I/O migration

What to consider:

- Keeps existing ET 200M hardware in place (for now)

- Can reduce project scope while giving you time to plan wiring changes

- Sets a foundation for phased replacement later

🔹 Option 3: Phased Modernization (Most Flexible)

Best for: Plants needing to minimize risk and spread upgrades over time

What it involves:

- Maintain mixed operation of ET 200M and ET 200SP HA

- Replace I/O segment-by-segment

- Use downtime windows for staged cutovers

- Leverage Profinet tools and SIMIT simulation for testing and risk reduction (suggested revised, key for me is PROFINET tools (like Proneta) and the simulation after SIMIT is not 100% required).

What to consider:

- Ideal for large or complex systems

- Allows early wins and longer planning cycles

- Requires careful tracking of mixed system architecture

There’s More Than One Right Way to Do This

These three strategies reflect Siemens’ recommended approaches — and they’re a helpful starting point. However, your actual upgrade path might depend on several other factors:

cabinet space, network constraints, legacy software, budget timing, or operational risk.

That’s why no two modernization plans are exactly the same. If you’re unsure where your system fits, we’re here to help you figure it out — and create a plan that works in the real world.

What This Upgrade Touches (Beyond the Hardware)

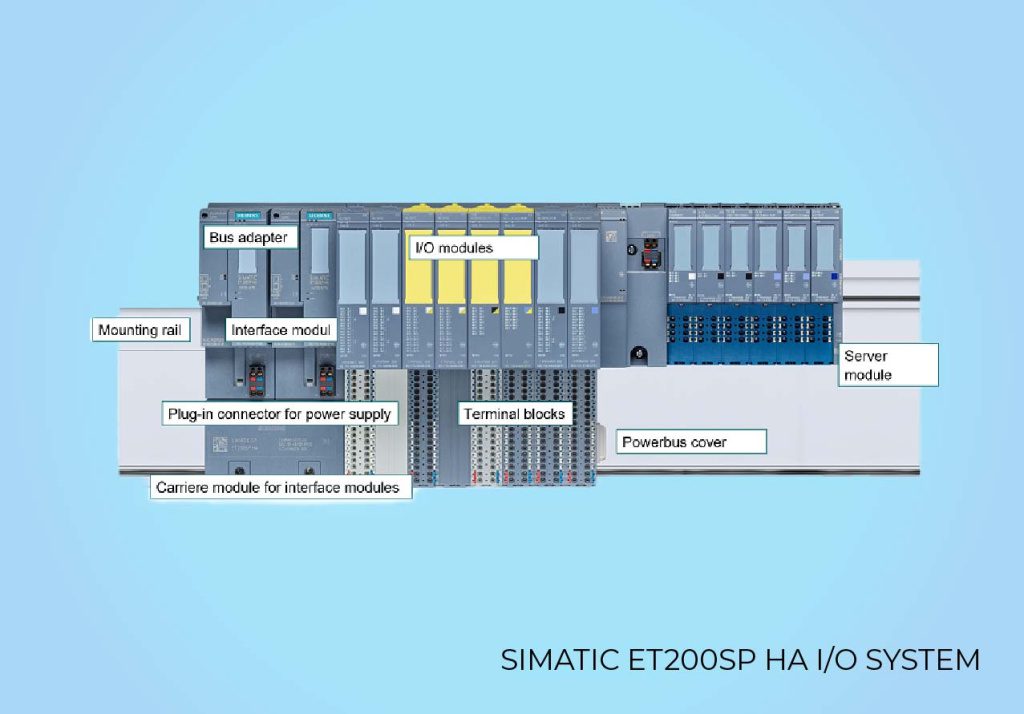

Upgrading from SIMATIC ET 200M to ET 200SP HA is more than just swapping I/O. It has ripple effects across your entire control system — wiring, networking, cabinet layouts, and project structure.

Here are a few areas that often need attention:

🧱 Cabinet Layout & Field Wiring

ET 200SP HA modules are more compact but denser, often requiring cabinet redesign. Field wiring might need extension or rerouting based on mounting position and space limitations.

🔌 Fieldbus Infrastructure

ET 200SP HA uses Profinet instead of Profibus. This necessitates changes in cabling, new network topologies, and validation of CPU and switch compatibility.

🧠 Symbol Mapping & Channel Block Compatibility

If your PCS 7 project isn’t already using APL blocks, you will probably need to update function blocks, symbol tables, and hardware configuration to support the new hardware.

🔄 Module Substitutions

Some ET 200M modules lack direct SP HA replacements. Siemens is expanding the portfolio, but some functions may require creative solutions or re-engineering.

⚙️ Mixed System Operation

Running ET 200M and ET 200SP HA side by side during a phased transition increases complexity — especially in diagnostics, firmware, and redundancy

It’s a Lot to Account For — But It Doesn’t Have to Be Overwhelming

This list isn’t intended to overwhelm; it’s meant to give you visibility.

These are the kinds of factors that appear in nearly every upgrade. Some are straightforward, while others require planning. But all of them can be handled — especially when you know what to expect.

🧠 Looking for practical, real-world guidance?

Visit our Technical Planning Page — a dynamic resource designed to grow with the challenges and solutions we face in the field. You’ll find layout tips, PCS 7 prep insights, Profinet transition notes, and practical knowledge from real upgrade projects.

How Pigler and Siemens Work Together to Support Your Upgrade

Pigler Automation has been a Siemens Solution Partner since our founding in 2004 — and our roots go even deeper. Our founders began their engineering careers at Siemens in Germany, working on the very technologies many plants still rely on today.

When you work with Pigler, you’re not just receiving integration support. You’re gaining a team that:

- Knows the ins and outs of SIMATIC ET 200M — and the real-world effort needed to replace it

- Develops upgrade plans aligned with Siemens’ best practices, tools, and support options.

- Helps minimize downtime, control risk, and operate within your plant’s realities.

- Brings Siemens resources, including simulation, validation, and migration guidance.

Whether you’re starting with a system assessment or mapping out a full I/O migration, we’ll help you take the next step with a plan that fits your plant — backed by Siemens tools and Pigler’s experience.