During a recent project, we helped a customer deploy a new Ignition system, replacing outdated, difficult-to-integrate platforms and establishing reliable communication across dozens of PLCs and multiple global teams. The goal: clean up and import over 1200 tags linked to Allen-Bradley PLCs while aligning with a distributed architecture already used overseas.

This project demonstrated how modern SCADA rollouts often become complex, not because of flawed design, but due to misaligned expectations, mismatched naming conventions, and region-to-region handoffs. “Unified Data” was a phrase we frequently heard, but the underlying schema told a different story. Inconsistent tag naming and frequent updates made it impossible to use UDTs—the very structure that would have made data unified and revision-controlled.

It also emphasized how much easier an Ignition SCADA tag import can be when the process begins with structure, validation, and testing.

Why Ignition Was the Right Fit

The customer had been using a combination of systems, including a legacy SCADA platform and a Foxboro-based DCS. While that worked in the past, it became increasingly difficult to scale and connect with newer systems.

Ignition offered a better path forward. It supports flexible communication with both legacy and modern hardware, scales easily across facilities, and provides a more open architecture. This rollout was designed as one of several “spokes” in a growing global network of Ignition gateways.

Building Connections, One PLC at a Time

The site had about 30 Allen-Bradley PLCs. We set up each one directly in the Ignition Gateway, choosing the right driver and verifying connectivity.

Since the system was new and hosted in a highly secure VM environment, we collaborated closely with the customer’s IT team. Together, we opened necessary ports, verified protocols, and navigated their strict firewall policies. Although their security standards weren’t always convenient, addressing them early helped prevent larger issues down the line.

Prepping for a Clean SCADA Tag Import

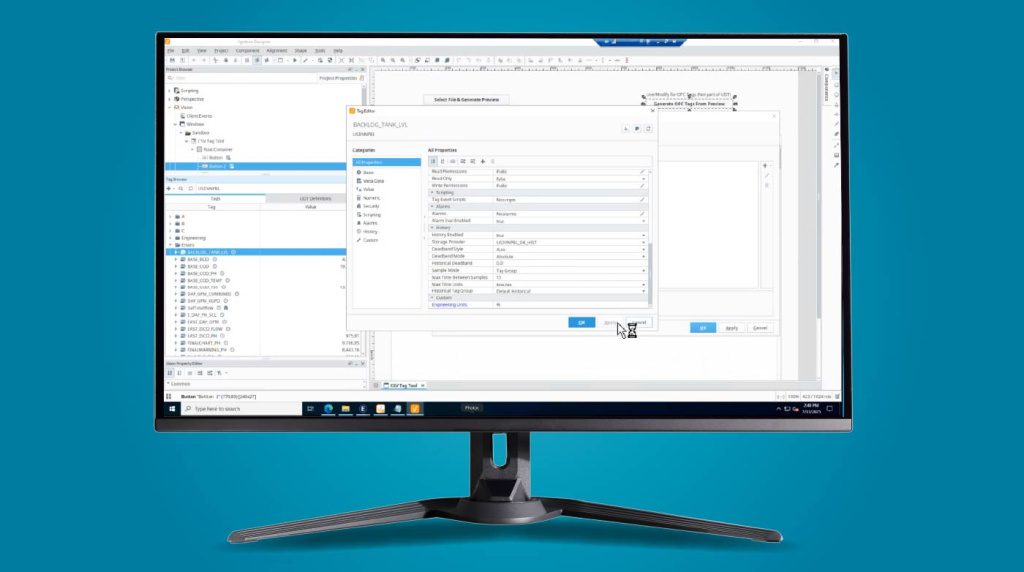

After setting up PLC connections, we proceeded to tag import. The source file contained over 700 entries—each with polling rates, folder paths, activation flags, and other metadata stored in a structured CSV.

Before importing anything, our engineers examined the file line by line. We looked for formatting errors, invalid characters, and folder mismatches. This careful upfront review gave us a solid foundation and prevented cascade errors later in the process.

The Two-Step Tag Import Strategy

To minimize risk, we used a two-step import process. For each PLC, we began by importing only five tags. These were used to test folder paths, addresses, and live data.

Once those tags passed validation, we proceeded with a full import for the remaining tags. We also used an “activate/deactivate” flag in the file. This allowed us to preload tags while keeping them inactive until the corresponding PLC was online—preventing red alarms or false diagnostics in the system.

The result: 733 tags imported cleanly, all in one pass.

What Could Have Gone Wrong: A Folder Path Mismatch

Just before the final import, we noticed a mismatch in the folder paths. A European team managing a parallel Ignition deployment had altered the tag directory structure but never shared those changes with the U.S. team.

If we hadn’t caught it, the tags would have been imported into invalid folders. They would still exist in the system but show red quality and fail to communicate. Any logic or visualization relying on them would have failed silently, causing hours of rework and confusion.

That’s the kind of issue that doesn’t throw a red flag until it’s already cost you time.

Final Validation and Cleanup

After fixing the folder paths and double-checking system alignment, we ran the full import. Live values appeared as expected in the Ignition tag browser. The historian grouped and recorded tags correctly.

We exported a backup for future reference. Then we fixed minor naming inconsistencies—like merging duplicate folders for “HVAC” vs. “H-VAC.” It was a small final step that made a big difference in how clean the system felt after launch.

5 Takeaways for Your Next Tag Import

If you’re expanding a SCADA system or connecting one site to a larger setup, here are some lessons worth keeping in mind:

- Agree on folder structures and naming conventions early

- Check your tag files for hidden characters or invalid syntax (like periods in tag names)

- Use small test batches before full imports

- Defer activation on tags tied to offline PLCs to avoid false alarms

- Keep a clean backup of your tag import structure for future reference

Helping You Get It Right the First Time

At Pigler Automation, we’re an Ignition Gold Certified Integrator with experience supporting projects in both greenfield and brownfield environments—from initial setup to cross-site integration and cleanup. Whether you’re importing 70 tags or 7,000, getting it right starts with good structure, consistent naming, and a few extra sanity checks along the way.