Why Teams Delay, and Why They Shouldn't

Don’t wait for a Crisis to Modernize

You don’t need a full system replacement to start upgrading

- Focus on critical pain points first

- Use simulation and parallel runs to avoid downtime

- Phased modernization reduces disruption and spreads cost

👉 Keep reading or skip to our 3 upgrade strategies below

It’s not that you don’t want to upgrade.

It’s that you can’t afford to get it wrong.

You’ve got production to protect, people depending on uptime, and a system that, while outdated, still runs. Not perfectly. Not efficiently. But it gets the job done.

And when you’re running 24/7, “getting the job done” can feel like all you can ask for.

So you wait.

Because downtime isn’t just inconvenient, it’s expensive. Because starting an upgrade means making a hundred decisions you’re not ready for. Because no one wants to be the one who pulled the trigger too soon.

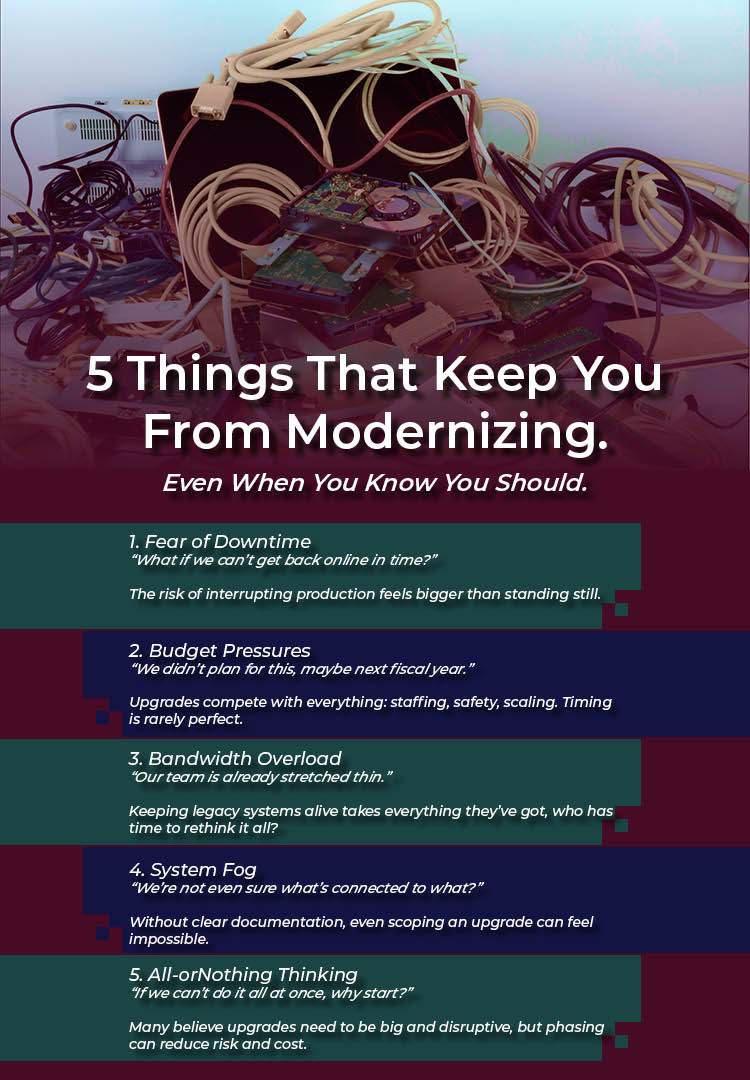

What’s Really Holding You Back

Sometimes it’s not about fear, it’s about the sheer complexity of the decision.

You’re managing shifting positions, limited headcount, and a system that’s been modified, patched, and reconfigured more times than you can count. Parts of it work well enough. Other parts are held together by institutional memory and crossed fingers. The uncertainty isn’t just about where to start, it’s about what might break open once you do.

And beneath it all lies a quiet belief that upgrading means disruption. If you can’t afford to replace everything, you’re stuck with what you have. But that’s the part we want to challenge because there is a way to move forward, not with a massive overhaul, but with clear, focused steps that respect your reality and make the process manageable.

A Smarter Way Forward: Phase It In

Here’s the good news. Modernization doesn’t have to be all or nothing.

You don’t need to rip out your entire system or approve a six-figure budget to make progress. The most successful upgrades we’ve seen aren’t large, sweeping changes. They’re carefully phased, quietly implemented, and aligned with the way your team already operates.

Phased modernization involves identifying the optimal starting point, whether it’s a failing PLC, unsupported HMI software, or a batch process that has become a maintenance burden. Address the most critical issue first, build momentum, and progress from there.

There’s less disruption, less downtime, and significantly less stress on your team. When you approach it with a plan, you’re not merely reacting to failure; you’re proactively building toward the future on your terms.

Three Strategies That Make Phased Modernization Work

🔧 Three Proven Strategies for Low-Risk Modernization

Click through each tab to explore field-tested ways to upgrade without disrupting production.

Every system has weak points, aging hardware, unsupported software, or components that still run but feel like they could fail with one wrong move. That’s your starting point.

We collaborate with teams to identify high-risk areas: What’s nearing end-of-life? What’s draining resources to maintain? What poses a safety or security concern if it fails? By concentrating on the parts of your system that carry the most risk or friction, you can start modernizing where it makes the most significant difference, without disrupting what still works well.

Simulation tools like Siemens SIMIT allow you to test control logic in a virtual environment, before anything changes in the real world. Think of it as a full-scale dry run, where your team can validate every sequence and scenario without touching a live system.

This kind of preparation means fewer surprises during commissioning, faster recovery if something doesn’t go as planned, and far less pressure on your operations team. Simulation isn’t just about safety, it’s about giving your upgrade the space to succeed.

You don’t have to flip the switch and hope for the best. You can often keep your existing system running while you gradually bring new components online. It’s a way to modernize with control, not chaos.

We’ve helped clients deploy new SCADA layers, test logic behind the scenes, or transition one line or area at a time. Running old and new systems side-by-side gives your team time to adjust, troubleshoot, and validate, without putting production at risk.

Three Strategies That Make Phased Modernization Work

- Start with the Critical Path

Every system has weak points, aging hardware, unsupported software, or components that still run but feel like they could fail with one wrong move. That’s your starting point.

We collaborate with teams to identify high-risk areas: What’s nearing end-of-life? What’s draining resources to maintain? What poses a safety or security concern if it fails? By concentrating on the parts of your system that carry the most risk or friction, you can start modernizing where it makes the most significant difference, without disrupting what still works well.

- Use Simulation to De-Risk the Upgrade

Simulation tools like Siemens SIMIT allow you to test control logic in a virtual environment, before anything changes in the real world. Think of it as a full-scale dry run, where your team can validate every sequence and scenario without touching a live system.

This kind of preparation means fewer surprises during commissioning, faster recovery if something doesn’t go as planned, and far less pressure on your operations team. Simulation isn’t just about safety, it’s about giving your upgrade the space to succeed.

- Run Systems in Parallel (When You Can)

You don’t have to flip the switch and hope for the best. You can often keep your existing system running while you gradually bring new components online. It’s a way to modernize with control, not chaos.

We’ve helped clients deploy new SCADA layers, test logic behind the scenes, or transition one line or area at a time. Running old and new systems side-by-side gives your team time to adjust, troubleshoot, and validate, without putting production at risk.

✅ Not sure where to start? These 3 strategies work best when used together—pick the one that fits your operation’s most urgent need.

You Don’t Need a Massive Overhaul. You Need a Clear Path Forward.

Modernization doesn’t have to be chaotic. You don’t need to risk downtime or commit to a complete system replacement to make progress.

What you need is a plan—one that is phased, practical, and tailored to how your operation runs.

At Pigler Automation, we specialize in helping teams like yours upgrade with confidence. Whether it’s identifying your system’s critical path, using simulation to reduce risk, or rolling out updates in controlled phases, we bring the tools, expertise, and support to make it manageable and successful.

If you’ve been waiting for the “right time,” take this as your signal. Let’s begin with one conversation.

🛠️ Ready to See Where Your System Stands?

Don’t guess—get clarity.

Download our Modernization Risk Snapshot Tool to quickly assess the health of your automation environment and identify where to start your upgrade.

✔️ Pinpoint high-risk areas

✔️ Prioritize modernization efforts

✔️ Share results with your team and leadership

👉 Complete the form to get the tool—and start planning with confidence.